EB coating 'nuclear' technology, why is it so excellent?

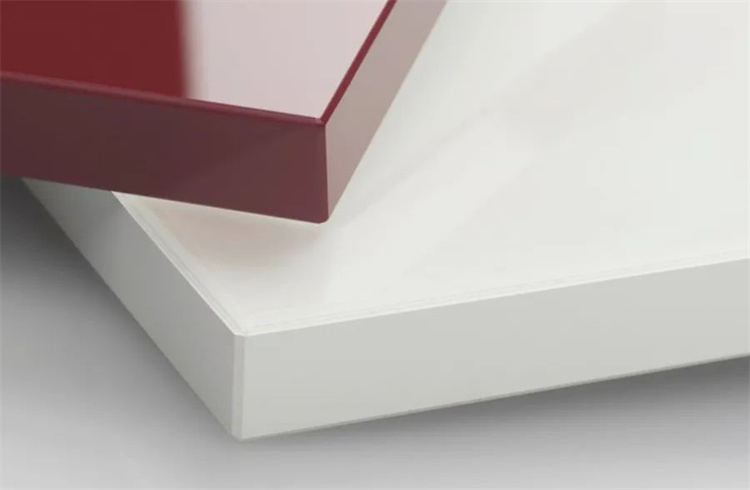

Guangdong Zhihua Group is the first company in China to apply EB electron beam curing technology to the decorative film materials. The application of EB electron beam curing technology can improve the performance of panel decoration in many aspects, such as weather resistance, sunlight resistance, yellowing resistance, pollution resistance, dirt resistance, easy cleaning, high scratch resistance, high hardness, grease resistance and chemical resistance.

Today we will conduct in-depth exploration and analysis of this process.

In the global manufacturing industry, there is a phenomenon of 'upstream determines downstream', where the downstream is likely to use the product developed by the upstream for research and development. There are very few completely independent upstream level achievements.

The same is true in the furniture manufacturing industry. The Engineered wood, decorative paper, film, hardware, etc. we see are all developed by upstream manufacturers before downstream manufacturers have application space. This is the result of different division of labor in modern industrialization, which is the best solution in the industrial era.

Thanks to the level of manufacturing development and industrial history in Europe, the quality of customized panels and hardware in the industry is extremely outstanding worldwide, receiving orders from around the world.

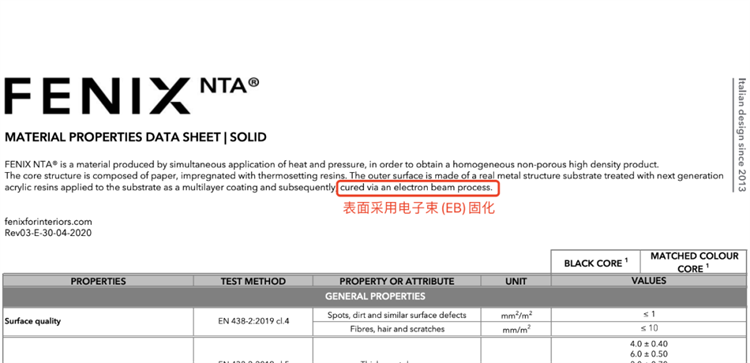

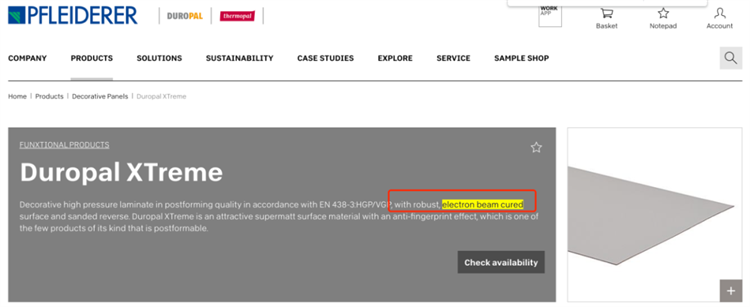

If further subdivided into the category of decorative panels, from Alvic, Arpa, FENIX, CLEAN Why is it that so many brands are being sought after by high-end and mid to high end brands in the Chinese market?

The design is creative, and European decorative panel brands have many innovative new products in their design. The research and development conducted with a global perspective has amplified the demand of a potentially small group.

The quality is guaranteed. For example, wear resistance, yellowing resistance, Hotfix, etc. are outstanding. The effect of both high gloss and matte is very good and stable.

There is no breakthrough in design in the short term, while the quality of Made in China has always been studied and explored. For example, in the Engineered wood manufacturing industry, we have achieved the quality not inferior to the European standard through the introduction of equipment from Germany, Finland and other countries.

In terms of decoration technology, we have already reached international advanced standards by purchasing raw materials or technologies such as water paint, paint, electrostatic powder spraying, and excimer. So why has China's decorative panels not yet achieved the same quality as Europe?

We believe that there are crucial factors in the curing process, and the higher the specification of the decorative panel, the higher the process requirements in the curing process.

This view has been confirmed on the official websites of many decorative panel brands. In addition to their high-end advantages, they also specially marked the use of EB electron beam curing process, which seems to prove that these advantages are Strongly correlated material to the use of this curing process.

The process of transforming coatings from liquid, powder, and other forms into solids is called curing. EB electron beam curing is one of the curing technologies in the coating process and is currently known as an industry-leading curing process.

At present, several processes and materials for the manufacturing of decorative panels include but are not limited to: paint, water paint, electrostatic powder spraying, excimer, decorative film, PET, decorative paper, etc.

paint, water-based paint, electrostatic powder spraying, and excimers all cannot avoid the curing process, including decorative film, decorative paper, PET, and other underlying processes. The current mainstream curing processes are: thermal curing, ultraviolet (UV) curing, and the emerging process is: EB electron beam curing.

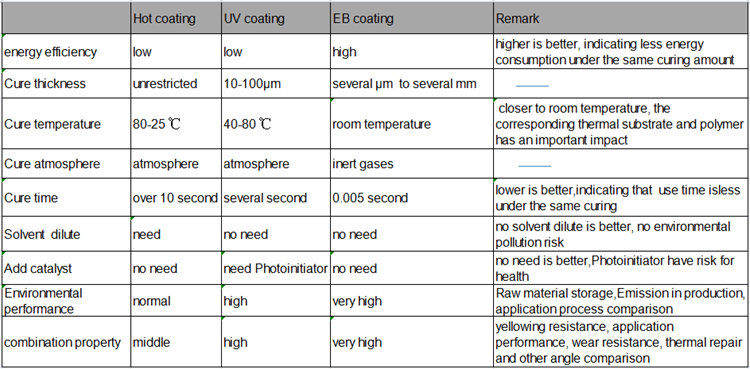

Based on previous research, we have drawn the following chart.

If you look at the curing thickness, does thermal curing seem more severe? In fact, thermal curing requires longer time for cured parts with higher thickness, resulting in higher energy consumption and invisibly increasing manufacturing costs.

Case reference for heat curing: This is a Ming Dynasty lacquered bowl with several millimeters of thick red paint on the surface. Bowls with this process require repeated coating and curing, and the curing process of turning the paint from a liquid state to a solid state for the finish often takes several days.

Even in modern times, this thermosetting process is very time-consuming because it requires a high heat baking room to cure it, which not only consumes a lot of energy (usually electrical energy converted into heat energy), but also takes a relatively long time.

There is also a solvent risk in thermal curing, as the application of solvents carries risks from production, transportation to final use, such as risks of combustion and explosion, volatile matter, etc.

If there are some problems with thermal curing, what about UV curing? This curing process is currently the mainstream process for mid to high-end brands and is popular due to its high environmental performance and efficiency, including the use of UV curing technology for popular excimer boards.

So is this process perfect? Currently, it is not. Mainly reflected in several aspects.

Curing thickness and balance, UV curing is only applicable to micron level paint films, which is the case for excimer and ordinary UV paints. Even at a thickness of only micrometers, research has shown that the thicker the paint film, the more prone it is to defects in the curing effect, and the more obvious is the phenomenon of uneven curing.

The application of photoinitiators does not require photoinitiators in the UV curing process of excimers, but other UV curing processes may result in residual photoinitiators, which pose health risks.

EB electron beam curing, low energy consumption, balanced curing, and better environmental performance are its visible advantages in the production end; On the consumer experience side, it has advantages such as weather resistance, sun resistance, yellowing resistance, dirt resistance, easy cleaning, high scratch resistance, high hardness, oil resistance, and chemical resistance.

As can be seen from the above table, EB electron beam curing does not require a high-temperature environment, solvents, photoinitiators, very low energy consumption, and a very fast curing speed.

Therefore, at present, EB electron beam curing is a highly outstanding curing process and is also known as a globally advanced curing process.

At present, the mainstream curing process is UV curing, and EB electron beam curing is actually better than UV in experimental and application aspects. The following is the relevant research literature data.

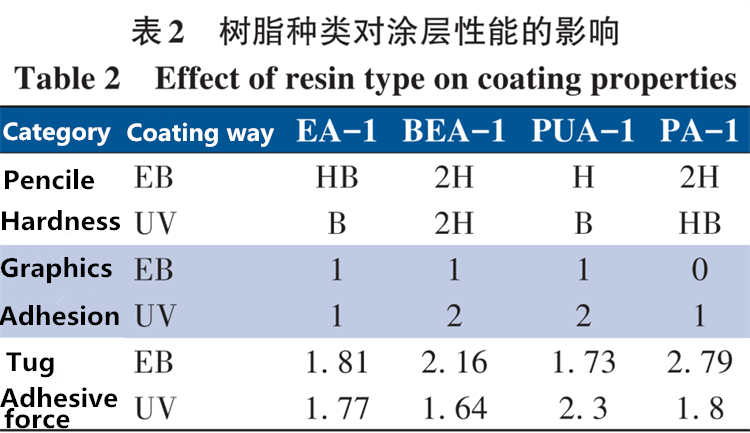

Pencil hardness: This test value corresponds to the scratch resistance of the product coating, and the higher the hardness, the better the stain resistance and scratch resistance.

Grade description: 6B, 5B, 4B, 3B, 2B, B, HB, H, 2H, 3H, 4H, 5H, 6H, 7H, 8H, 9H, from soft to hard, this is the result expression of pencil hardness measurement method for film hardness.

The results showed that in the hardness part of pencils, EB cured in different resins had higher hardness than UV cured.

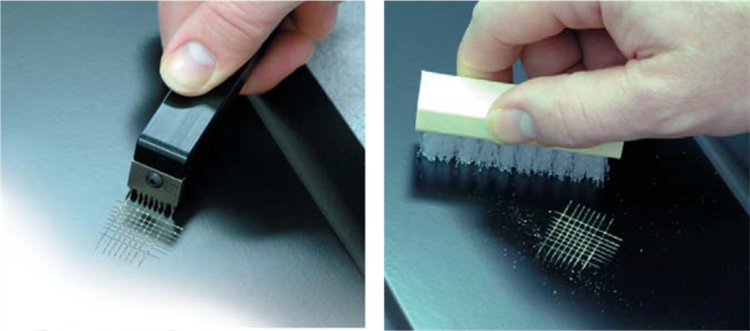

Scratch adhesion: This value corresponds to the adhesion of the coating and also has significance for scratch resistance and durability. The smaller the value of 0-6, the better.

Level description: Level 0, 1, 2, 3, 4, 5, 6, a total of 6 levels, divided by indicators such as cutting edge effect, coating detachment ratio, and affected area.

The results showed that EB curing was also superior to UV curing in terms of adhesion to the grid, resulting in better adhesion.

Pulling adhesion: This value corresponds to the adhesion between the coating and the substrate after curing, which is meaningful for scratch resistance and durability. The larger the value, the better.

The results showed that in the aspect of pull-out adhesion, EB electron beam curing was superior to UV curing except for its weaker resin value in PUA-1 compared to UV curing.

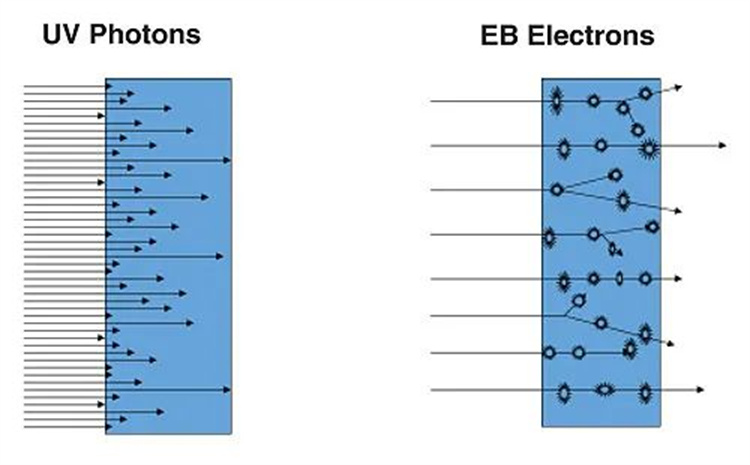

Why is the hardness of EB curing higher than that of UV curing?

In general, 350 nm UV photon energy=3 5 keV is equivalent to the electron energy at a voltage of 110 kV, and the condition for electron beam solidification is 220 keV. Therefore, in terms of energy, the energy of the electron beam is higher than that of UV photons.

Therefore, after EB electron beam curing, the surface chain cross-linking network density of the coating is higher, which can enhance the surface hardness of the coating. Why is EB curing more adhesive than UV curing?

The adhesion test results show that the adhesion of EB cured coatings is generally higher than that of UV cured coatings, regardless of whether it is a cross cut test or a pull out test. This may be because wood is a natural polymer material, and the electron beam penetrates the coating to change its surface chemical structure, which makes the coating interact with the base wood by Chemical bond, improving the adhesion of the coating to wood.

Simply put, EB electron beam curing is more thorough than UV curing, making the coating material harder, resulting in stronger adhesion.

'Hotfix' is not a new term in other application fields. For example, the invisible car coat of a car has the ability of 'Hotfix'. The invisible car coat is made of TPU material and can be repaired at a certain temperature without particularly deep scratches.

Principle: TPU material has close molecular structure, good strength and high tensile ratio. When scratches are generated by external forces, molecules rupture. When the external force is withdrawn, the molecule will produce fission elongation. Under the effect of temperature, the damaged molecular structure can be automatically restored to repair scratches.

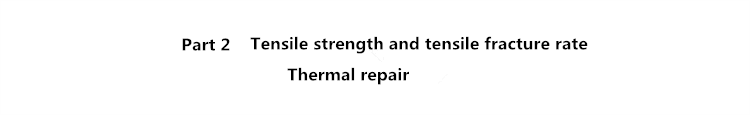

In the comparison of 'Hotfix force' of EB electron beam curing and UV curing, we focus on two data, tensile strength and tensile fracture rate.

Tensile strength: The tensile resistance of the coating, the larger the value, the better.

The results show that the tensile strength of EB cured by electron beam is higher than that of UV cured, which indicates that the tensile resistance of EB cured by electron beam is stronger, and the Hotfix force is stronger.

Elongation at break: It is generally expressed as the relative elongation at break, which is the ratio of the elongation at break of a fiber to its initial length, expressed as a percentage. It is an indicator that characterizes the softness and elasticity of the sample, and the higher the elongation at break, the better its softness and elasticity. The results showed that except for PUA-1 with a slightly lower elongation at break than UV curing, EB electron beam curing was stronger than UV curing. Therefore, the coating cured by EB electron beam has stronger Hotfix performance, while other curing methods do not have Hotfix capability or are weaker than EB electron beam curing.

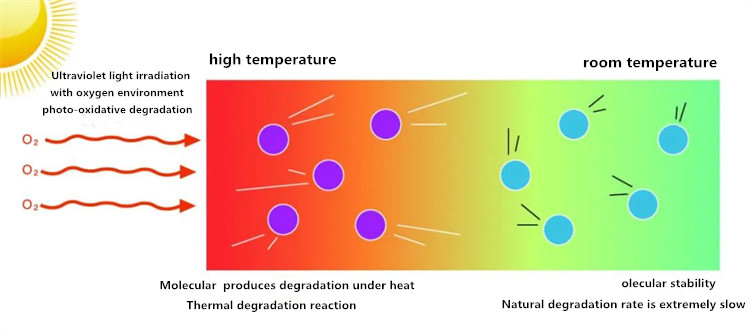

Whether it is furniture, cars, or clothing, after prolonged use, light colored furniture often experiences yellowing, with white or light colored furniture and cars being the most obvious, causing headaches for multiple industries. We need to know how yellowing occurs? The main ways of coating aging and yellowing are thermal degradation, oxidative degradation, and photooxidative degradation of polymer chains, which means there are three main conditions that cause the coating to turn yellow: sunlight, oxygen, and thermal energy.

The coating undergoes two irreversible chemical reactions, degradation and cross-linking, in the environment of photooxygen and thermal oxygen, which leads us to see the coating turn pale yellow, also known as 'yellowing'.

Is the yellowing resistance of EB electron beam curing outstanding?

1. EB electron beam curing does not use the photoinitiators required for UV curing, and there will be no residual photoinitiators in subsequent products. The photooxidative degradation rate under sunlight will be significantly reduced.

2. EB electron beam curing Because the coating is cured thoroughly, the molecular structure is tight, and the probability of 'invasion' by oxygen molecules is greatly reduced. Under the intervention of a lack of oxygen, the chemical reaction of hot oxygen is also greatly suppressed. Based on these reasons, the yellowing resistance of EB electron beam curing is excellent, and the experimental results show that it is far superior to other curing processes.

Taking paint as an example, we know that it is composed of film-forming substances, pigments, and other formulations. In the curing process, UV curing has a better effect on film-forming materials with higher transparency, while those with lower transparency may experience incomplete curing.

EB electron beam curing does not require attention to the transparency of the film-forming material, and the process is almost the same as room temperature, resulting in a very low probability of thermal reaction of the coating. Due to the participation of thermal energy in both thermal and UV curing, there will be thermal reactions on the coated parts and coatings, which will have an impact on the color of the product. Therefore, EB curing is more stable.

In addition, EB electron beam curing can also be programmed to accurately process coatings of different thicknesses, resulting in rich curing results. Based on these situations, EB electron beam curing is more diverse in coating color compared to UV curing and thermal curing.

Now that the problem has returned to the upstream equipment supply chain, why did domestic decorative panel manufacturers not choose the EB electron beam curing solution? Cost, technology, market. There are only three global suppliers of EB electron beam curing equipment, all of which are foreign brands with high application costs. Moreover, the technology (solution) is also constrained by the supply chain, and service efficiency will be greatly affected. In addition, there is the market. Before the popularity of high definition in China, the Chinese customization industry mainly focused on solving the demand market. The quality requirements of products were still at a relatively basic level, such as environmental protection and physical performance requirements, such as formaldehyde content, deformation resistance, and processing performance. The release and delivery of the first set of electronic beam curing equipment for sheet metal in China, following the popularity of Gaoding, has driven the upgrading of the entire industry chain. Consumers and brands pay more attention to the quality of the veneer, from texture to the application performance of the veneer layer. To achieve better quality, it is necessary to upgrade from equipment to process. This is also the reason why Guangdong Zhihua Group has introduced EB electron beam curing equipment and technology.

Guangdong Zhihua Group's application of EB electron beam curing technology to decorative film materials will have a huge impact on the decorative panel industry, especially the application performance of decorative panels will be significantly improved, breaking the restrictions of some tactile and visual effects that can only be produced by imported brands, and making high-quality decorative products enter more Chinese families.